Advanced Recycling in West Virginia

Advanced recycling breaks plastics down into their molecular components and reuses them, allowing more types of plastics to be recycled than traditional methods. Currently, an advanced recycling facility is being constructed near Belle. This Science and Technology Note builds upon previous work exploring advanced recycling, adding further detail about the processes used and policy options used to regulate them in other states.

Updated January 30, 2026

Research Highlights

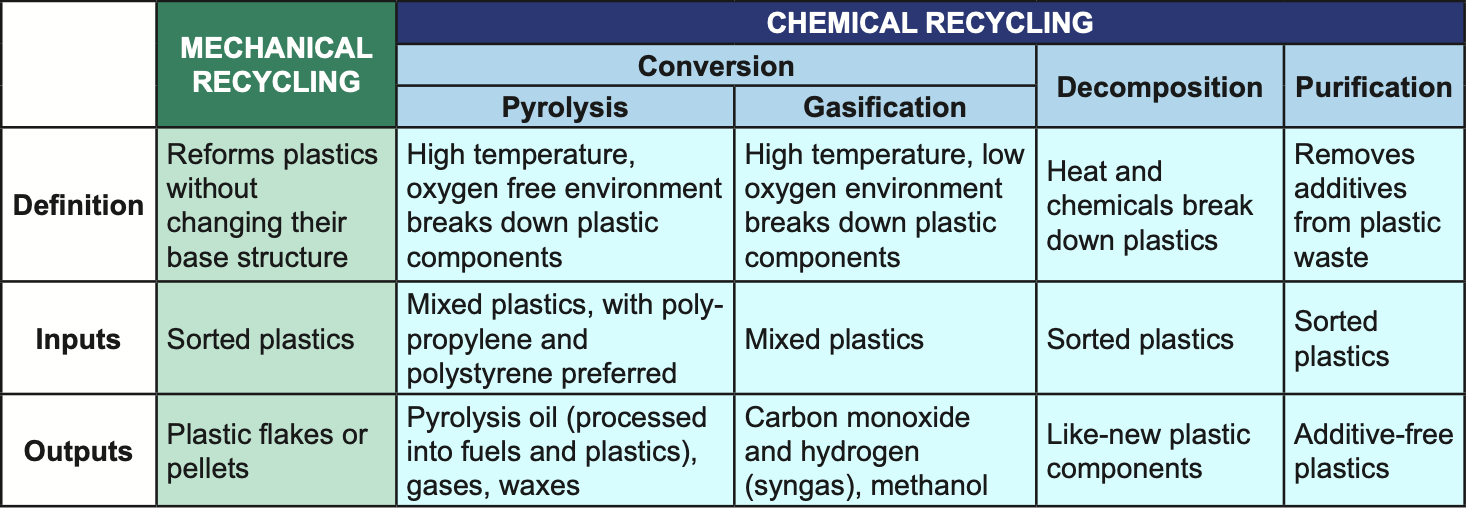

Conversion, decomposition, and purification are advanced recycling technologies that can expand upon traditional plastic recycling.

While advanced recycling technologies provide an expanded avenue for recycling, they may produce environmental and health impacts.

Some advanced recycling projects have stalled due to financial issues, including one project in West Virginia.

Advanced recycling regulations are rapidly changing; 25 states exempt it from solid waste classification.

Advanced recycling breaks plastics down into their molecular components and reuses them, allowing more types of plastics to be recycled than traditional methods. Currently, an advanced recycling facility is being constructed near Belle. This Science and Technology Note builds upon previous work exploring advanced recycling, adding further detail about the processes used and policy options used to regulate them in other states.

What is Advanced Recycling?

Currently, West Virginia recycles 2% of its plastic, lower than the US rate of 9%. Most recycled plastic undergoes mechanical recycling, where it is shredded and reformed. The plastic chemicals are not changed, in contrast to advanced recycling technologies. Advanced recycling uses chemical processes to alter the structure of plastic, allowing plastic waste to be recycled into like-new plastics, other chemicals, and fuels that can be used on-site to help power facilities. Mechanical recycling is like separating a trail mix into its ingredients and then recombining them to make your own custom mix, while advanced recycling is more like removing the peanuts from trail mix and making peanut butter. Advanced recycling includes conversion (pyrolysis and gasification), decomposition, and purification. Of these processes, pyrolysis is the most studied and commercially viable technology.

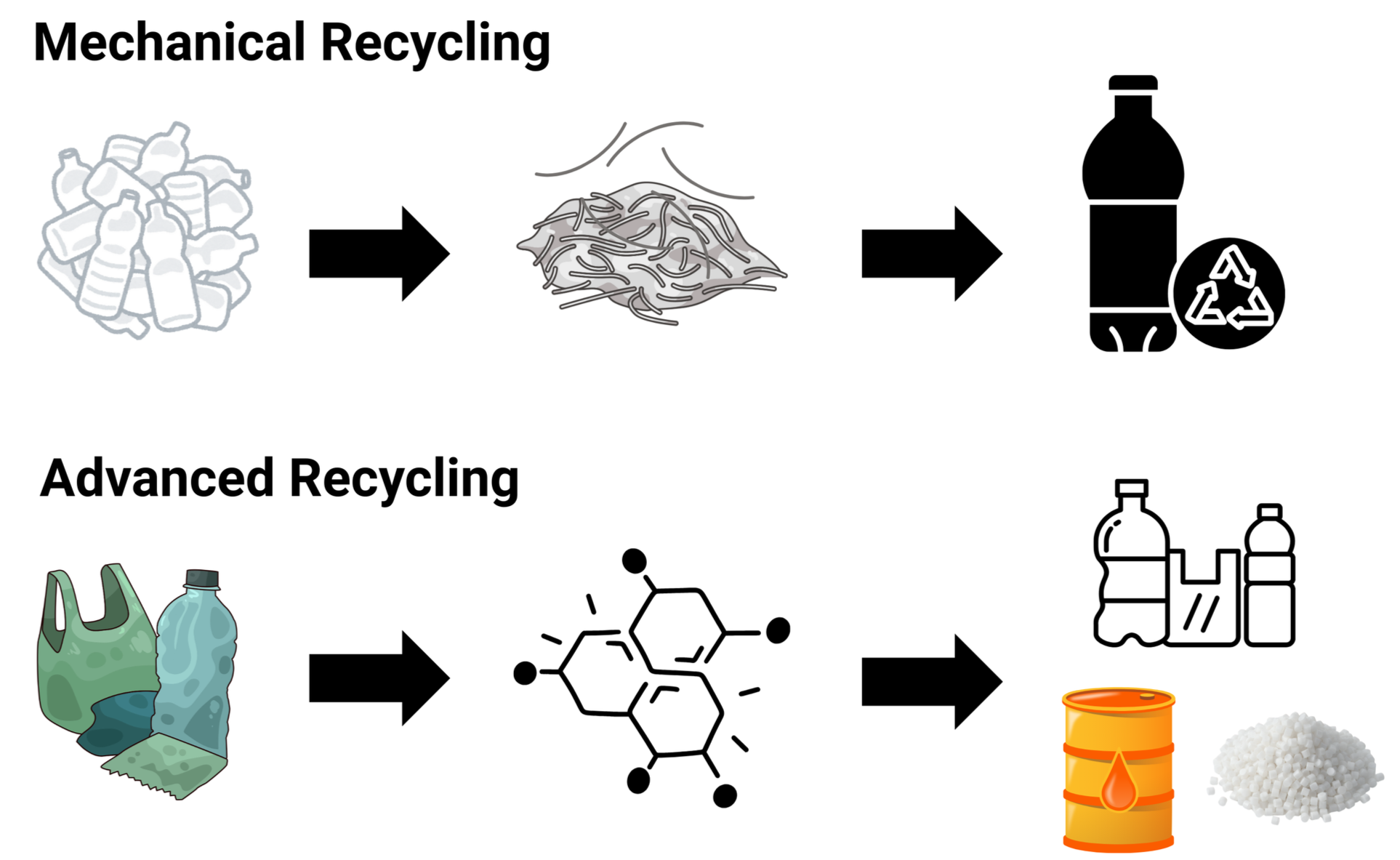

Mechanical recycling shreds and reforms plastic, while advanced recycling modifies the chemical makeup of plastics to make like-new plastic and other products.

Advanced recycling can accept more types of plastic than mechanical recycling, and can recycle plastics for use in food packaging that would typically require new plastics. A 2021 US Government Accountability Office report highlighted the potential of advanced recycling to decrease fossil fuel demand, reduce the amount of plastic waste directed to landfills, and create new jobs. The report also identified challenges to advanced recycling uptake, including high costs, process requirements, and competition with traditional plastics manufacturers.

Although advanced recycling expands the types of plastic that can be recycled, the complexities of various processes and differing assumptions between studies lead to large variations in data describing the environmental impacts of advanced recycling. A 2023 Department of Energy (DoE) study found that the environmental and economic costs of pyrolysis are 10 - 100 times greater than using new plastic due to low yields, though it noted that pyrolysis may be viable to create plastic components and other chemicals. A study of 9 advanced recycling plants conducted by Closed Loop Partners, a waste reduction company, found that advanced recycling could result in reduced energy requirements and greenhouse gas emissions. Citizens in areas surrounding proposed pyrolysis plants often cite concerns over emissions and safety. One pyrolysis facility in Ohio, for example, was found to have released hazardous chemicals into the air at least three times in 2025. Reports also note that many advanced recycling facilities have struggled, including those in Ohio and Indiana.

Clean-Seas, an advanced recycling company, is constructing a new facility in Belle with the capacity to process 50 tons of plastic per day and the capability to expand to 200 tons per day. They and other advanced recycling advocates point to a 2023 DoE study finding that manufacturing products using 5% pyrolysis oil instead of new plastic has environmental benefits, including reduced water and energy use. However, this study analyzed results using assumptions from an “Nth-plant,” a hypothetical facility with mature technology.

Advanced recycling facilities can have large economic impacts on communities. The American Chemistry Council, which includes America’s Plastic Makers, estimates that recycling 50% of municipal waste plastic would generate over 170,000 jobs and $48 billion nationally. The Clean-Seas facility in West Virginia is predicted to produce 40 full-time jobs through a $50 million investment, leveraging $12 million in state incentives. Clean-Seas has proposed increasing revenue by accepting plastic waste from neighboring states without advanced recycling facilities. Empire Diversified was seeking to open an advanced recycling plant in Follansbee, which was projected to generate 38 full-time jobs and $28,000 in local tax revenue. However, they were sued and filed for bankruptcy after failing to make a bond payment in 2025. The outcome of the case and facility is uncertain.

Policy Options

At the federal level, the Recycling Technology Innovation Act was recently introduced, aiming to exclude advanced recycling facilities from solid waste facility emissions regulations. West Virginia classifies advanced recycling as a manufacturing process, qualifying advanced recycling companies for additional benefits, including tax credits. This is similar to 18 other states, including Ohio, Kentucky, Pennsylvania, and Virginia.

Based on analysis by Beveridge & Diamond.

Fuel production from advanced recycling facilities could be a policy concern in West Virginia. Kentucky, Arkansas, and Michigan all prohibit advanced recycling from generating fuels, limiting facilities to production of materials that can be used in new plastics. Proponents of this legislation claim that using plastic products for fuels is not actually recycling them, and by narrowing the scope they enable more new, usable plastic to be made. Additionally, as generated fuel is often used to power the advanced recycling facility, it decreases the need for other energy inputs such as coal or natural gas. This may be an important factor in West Virginia, as both industries are prominent in the state.

This Science and Technology Note was prepared by Madison Flory, PhD and Nathan G. Burns, PhD, West Virginia Science & Technology Policy Fellows, on behalf of the West Virginia Science and Technology Policy (WV STeP) Initiative. The WV STeP Initiative provides nonpartisan research and information to members of the West Virginia Legislature. This Note is intended for informational purposes only and does not indicate support or opposition to a particular bill or policy approach. Please contact info@wvstep.org for more information.

Addendum: Mass Balance Attribution

What is mass balance attribution?

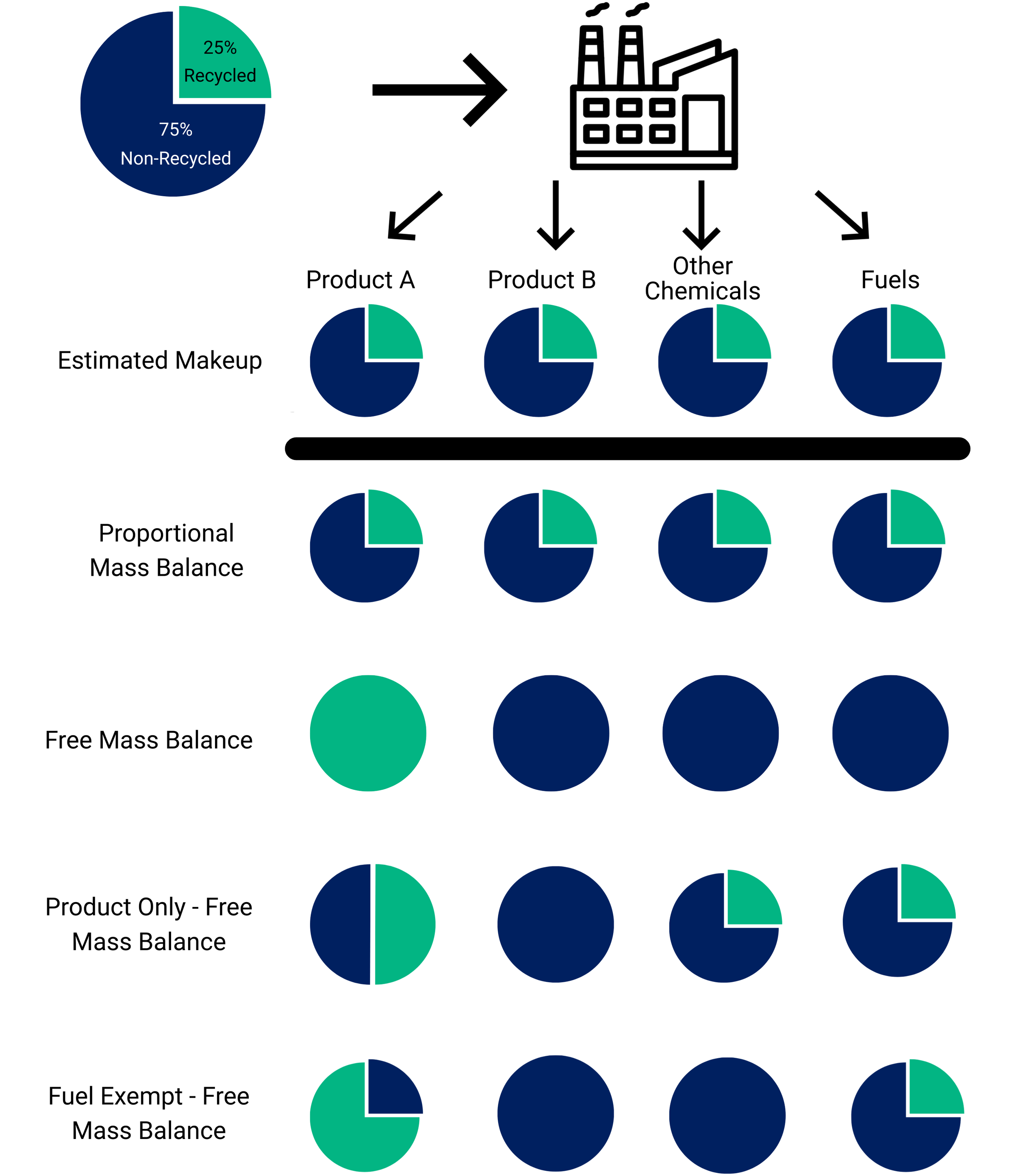

Mass balance attribution is a way of keeping track of the amount of recycled versus non-recycled materials in a product. It relies on various third-party certification systems to verify companies’ recycling claims. It is a key way to track recycled materials in products generated from advanced recycling, which breaks plastics down to the point that recycled and non-recycled components cannot be distinguished from one another. Mass balance attribution has been widely used for products including cotton, timber, cocoa, and tea for over 20 years.

How are mass balance attributions calculated?

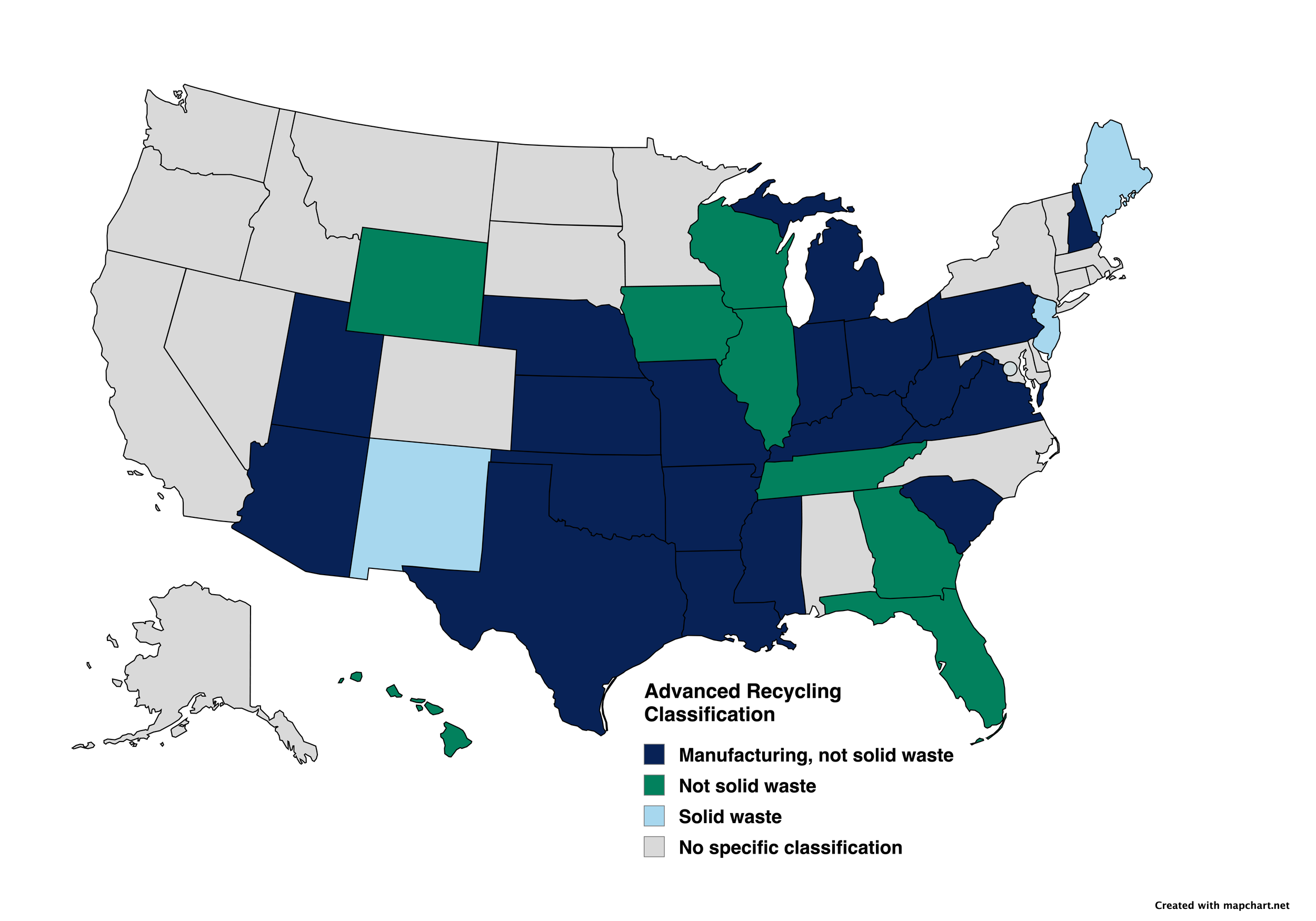

There are several different ways that mass balance attributions can be calculated. Broadly, they are broken down into proportional and non-proportional, or free, allocation. Proportional mass balance attribution equally distributes recycled materials among each product. For example, if a company uses 75% non-recycled material and 25% recycled material to produce 4 products, each individual product will contain an estimated 75% non-recycled and 25% recycled material. Proportional mass balance attribution requires that each product would be sold as 75% non-recycled and 25% recycled. Free mass balance attribution would allow those amounts to be unequally assigned to the same products, allowing 1 product to be sold as 100% recycled if the other 3 products are then sold as 100% non-recycled. Sometimes there are additional restrictions that require any fuels or chemicals produced to reflect the input balance, while any plastic products produced may use free allocation.

Free mass balance attribution is more beneficial for companies, as it allows them to sell individual products at higher recycled percentages and higher prices than proportional mass balance would allow. Using the profits from free mass balance allocation has been suggested as one method to help fund large scale advanced recycling infrastructure. Free mass balance attribution can be controversial because recycling percentages can be shifted between each item, even though the same amount of recycled and non-recycled material is used throughout the manufacturing process.

How do mass balance attribution certifications affect advanced recycling?

In 2023, the Texas Legislature added mass balance attribution to the state code. Since then, the Texas Commission on Environmental Quality has approved 7 mass balance certification programs for use in the state, including the Recycled Material Standard, the SCS Certification Standard for Recycled Content, and the International Sustainability & Carbon Certification (ISCC) PLUS standard. Programs can use different methods of calculating mass balance, but all include stipulations for record-keeping and compliance verification. The Recycled Material Standard is targeted towards small businesses and prefers proportional allocations, while the SCS and ISCC standards allow for free allocation.

Using certification programs to verify mass balance attributions ensures that all companies using the same standards are meeting the same requirements, helping to increase transparency and consumer confidence.

Different methods of calculating mass balance for products made from a mix of recycled and non-recycled inputs can lead to companies’ ability to claim some of their products are made of more recycled material. Adapted from Clariter.